Trailer Landing Gear

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality testing passed by an independent lab

Warranty: 16 months since shipping date

100% quality inspection before shipment

Oversea sales volume (pairs): 50,000+

Product Description:

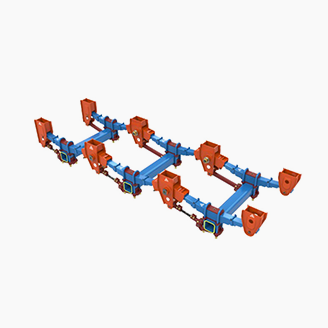

Trailer landing gear, often referred to as landing legs, is a vital component of semi-trailers, providing support and stability when the trailer is detached from a tractor. Here’s a closer look at its features, types, and benefits:

Features

Support Legs: Typically consists of two adjustable legs, one on each side of the trailer's front.

Crank Mechanism: Many landing gears use a hand crank to extend and retract the legs. Electric options are also available for easier operation.

Height Adjustment: Allows the landing gear to be adjusted to different heights, accommodating various loading docks and tractor heights.

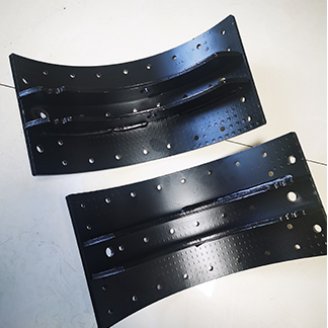

Durable Construction: Made from robust materials to withstand heavy loads and harsh conditions.

Types

Manual Landing Gear: Operated using a hand crank. While reliable, they require physical effort.

Electric Landing Gear: Features an electric motor for easy operation, particularly useful in high-volume loading situations.

Heavy-Duty Landing Gear: Designed for trailers carrying heavier loads, these often have reinforced structures for added durability.

Benefits

Stability: Keeps the trailer upright and stable during loading and unloading operations.

Safety: Reduces the risk of accidents by providing secure support when the trailer is detached.

Efficiency: Facilitates quick and easy transitions between loads, enhancing overall operational efficiency.

Versatility: Adjustable height allows use in various scenarios, from loading docks to uneven surfaces.

Maintenance

Regular maintenance is crucial for landing gear to ensure smooth operation and safety. This includes:

Lubrication: Keeping the crank mechanism and moving parts well-lubricated.

Inspection: Regularly checking for wear and tear, and ensuring that bolts and connections are secure.

Cleaning: Removing dirt and debris that may affect functionality.

Product Parameters:

Model | Static Load | Static Load | Gear Box Model | Weight | Height(A) | Lifting(D) |

XH-25T | 25000kg | 72000kg | Inside | 102kg | 840mm | 480mm |

XH-28T | 28000kg | 80000kg | Outside | 105kg | 840mm | 480mm |

XH-30T | 30000kg | 85000kg | Outside | 108kg | 853mm | 480mm |

Application:

Trailer landing gear is essential for various applications in the trucking and logistics industry. Here are some of the primary applications:

1. Loading and Unloading

Support: Provides stability while the trailer is detached from the tractor, allowing for safe loading and unloading of cargo at docks or warehouses.

Accessibility: Ensures that workers can safely access the trailer without the risk of it tipping or rolling.

2. Parking and Storage

Stability: Keeps the trailer securely in place when parked, reducing the risk of movement or accidents.

Space Management: Allows trailers to be parked independently, freeing up dock space for other operations.

3. Freight Transfer

Quick Attach/Detach: Facilitates rapid changes between different tractors or trucks, improving efficiency in freight operations.

Multi-Load Management: Useful for switching trailers with varying loads, especially in distribution centers.

4. Roadside Repairs

Support During Repairs: Provides a stable base when a trailer needs to be serviced or repaired on the road.

5. Emergency Situations

Upright Stability: Ensures the trailer remains upright in case of a tractor failure or accident, helping prevent further damage or injury.

6. Specialized Operations

Custom Applications: Some trailers are designed for specific cargo types (e.g., refrigerated, flatbed) and the landing gear can be adapted for those needs.

7. Docking Operations

Ease of Use: Helps maintain alignment and stability when backing into loading docks, making the docking process safer and more efficient.

8. Transporting Heavy Equipment

Heavy-Duty Support: Provides the necessary support for trailers carrying heavy machinery or equipment, ensuring stability during loading and unloading.

9. Event and Exhibition Logistics

Setup Support: Used for trailers that transport displays or equipment for events, providing stability during setup.